01

ZX-1500/ZX-4800/ZX-7000 CNC blind hole special machine

MAIN TECHNICAL FEATURES

1. The main parts of the machine tool such as the bed, column, worktable and spindle box are all made of high-quality gray cast iron with high seismic resistance. They are produced by professional enterprises that have passed ISO9000 quality system certification. The casting process adopts special processing to improve the mechanical properties of the material. The casting has been aged twice to eliminate residual stress inside the material, so the machine tool has excellent rigidity and excellent shock absorption; it also has good thermal stability and long-lasting accuracy stability.

2. The main joint surfaces of the machine tool assembly are carefully scraped manually to ensure the effective contact area of the joint surfaces.

3. The spindle adopts a precision spindle unit produced by a professional manufacturer, and the spindle bearings adopt world-famous brand high-precision angular contact thrust ball bearings to ensure that the spindle has extremely high precision and rigidity. The spindle and motor pulley have been dynamically balanced tested to ensure the accuracy and life of the spindle.

4. The feed component of the machine tool adopts imported high-precision ball screws, and the support bearings at both ends adopt imported special screw bearings, and the ball screws are pre-stretched; the screw-motor connection adopts a gap-free elastic coupling , transmission has no gap, small moment of inertia and high transmission stiffness.

5. The machine tool is designed using X/Z-axis roller linear rails, and the two-way linear rails adopt heavy preloading, so that the machine tool not only takes into account the characteristics of high speed and high precision, but also has the characteristics of heavy cutting, with excellent rigidity and productivity efficiency.

6. The screw and guide rails are equipped with centralized automatic lubrication devices, which automatically supply oil to the screw and guide rails at regular intervals to ensure that the machine tool is fully lubricated during movement, thus ensuring that the machine tool has excellent rapid response characteristics and low-speed feed performance. , longer service life and better accuracy retention.

7. The CNC system is GSK-980MDI, which is the latest generation of CNC system configured with bus absolute servo motors.

8. Equipped with a high-precision servo indexing plate to realize automatic indexing and positioning of workpieces; the indexing plate is equipped with a hydraulic chuck to realize automatic clamping and loosening of workpieces.

9. Equipped with a blind hole depth sensor, blind hole processing and depth detection are performed simultaneously to accurately ensure the blind hole depth requirements.

10. An automatic loading and unloading system is optional to minimize the number of operators and reduce the labor intensity of personnel.

Project |

Unit |

ZX-1500 |

ZX-7000 |

Workpiece diameter range |

mm |

Φ51-Φ89 |

Φ51-Φ178 |

Maximum work piece length |

mm |

1220 |

6400 |

X-axis travel |

mm |

1500 |

6800 |

Z-axis travel |

mm |

350 |

400 |

X/Z axis positioning accuracy |

mm |

0.012 |

0.06/0.012 |

X/Z axis repeat positioning accuracy |

mm |

0.01 |

0.04/0.01 |

Spindle hole taper |

BT50 |

||

Spindle speed range |

r/min |

0-6000 |

|

Servo main motor rated power |

kw |

11 |

|

Chip removal method |

Spiral chip conveyor |

Chain plate chip conveyor |

|

Spindle protection/cooling method |

Air curtain protection, processing cooling, processing air blowing |

||

Compressed air for machine tools |

Kgf/cm2 |

6~8 |

|

Machine tool dimensions |

mm |

3300×1700×2600 |

10500×3000×2500 |

Machine weight (approx.) |

kg |

5000 |

13000 |

Vertical Machining Center

Vertical Machining Center Horizontal Machining Center

Horizontal Machining Center All Gear Heavy Machining Center

All Gear Heavy Machining Center All Gear Moving Column Type Heavy Machining Center

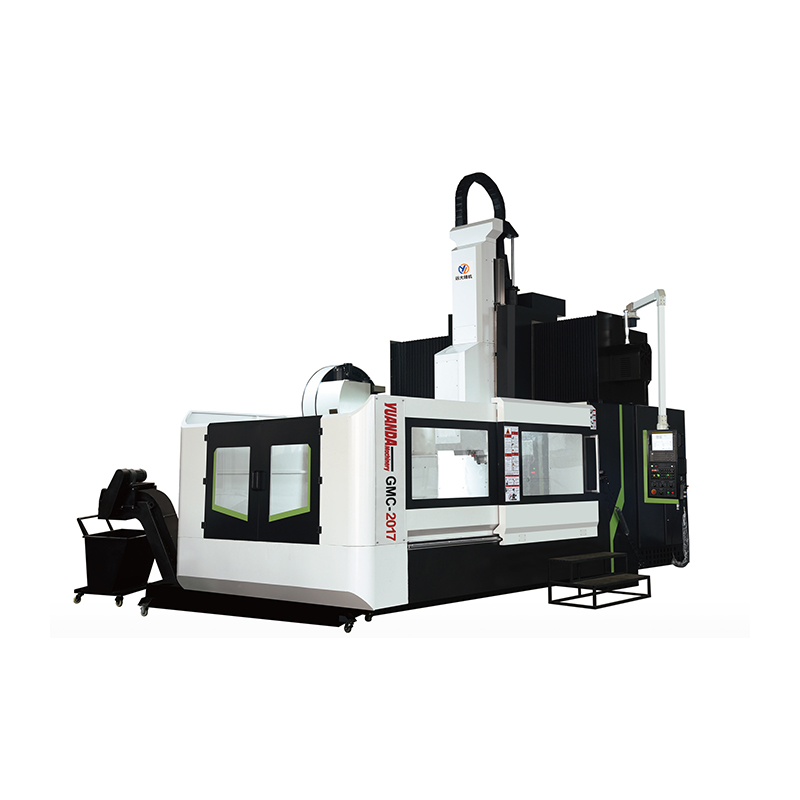

All Gear Moving Column Type Heavy Machining Center Gantry Machining Center

Gantry Machining Center All Gear Gantry Heavy Machining Center

All Gear Gantry Heavy Machining Center Oil Perforating Gun Blind Hole Special Plane

Oil Perforating Gun Blind Hole Special Plane