ZMC-1165/1380/1580/2080

Project |

Unit |

ZMC-1165 |

ZMC-1380 |

ZMC-1580 |

ZMC-2080 |

Workbench area |

mm |

1300×600 |

1500×800 |

1600×800 |

2100×800 |

Maximum load-bearing capacity of workbench |

kg |

800 |

1400 |

1500 |

2000 |

T-shaped slot (number of slots-slot width x slot pitch) |

mm |

5-18×120 |

7-18×110 |

7-18×110 |

5-22×160 |

X/Y/Z axis travel |

mm |

1100×650×650 |

1300×800×700 |

1500×800×700 |

2000×800×700 |

Distance from spindle end face to worktable |

mm |

170-820 |

150-850 |

150-850 |

150-850 |

Distance from spindle center to column guide surface |

mm |

681 |

859 |

859 |

859 |

Spindle maximum speed |

rpm |

5000 |

|||

Spindle hole taper |

|

BT50 |

|||

Spindle transmission mode |

|

gear drive |

|||

Gearbox output reduction ratio |

|

High speed range: 1:1.02 / Low speed range: 1:3.11 |

|||

X/Y/Z axis guide rail |

|

X/Y: Ball rail Z: Hard rail |

|||

Number of Y-axis tracks |

|

2×55 rail /4 slider |

4 rail / 8 slider |

||

X/Y/Z axis rapid movement |

m/min |

24/24/16 |

16/16/16 |

||

Maximum cutting feed rate |

m/min |

5 |

|||

CNC system |

|

FANUC OI-MF5PLUS |

|||

main motor power |

Kw |

15/18.5 |

|||

Tool magazine type |

|

Disc type |

|||

Tool magazine capacity |

|

24 |

|||

Maximum tool diameter/length |

mm |

Φ112/300 |

|||

Maximum tool weight |

kg |

18 |

|||

Spindle and gear cooling system |

|

Standard constant temperature oil cooler |

|||

positioning accuracy |

mm |

X/Y/Z:0.01 |

X:0.012 Y/Z:0.01 |

||

Repeatability |

mm |

X/Y/Z:0.008 |

X:0.01 Y/Z:0.008 |

||

air demand |

kg/cm² |

≥6 |

|||

Air flow |

m³/min |

≥0.5 |

|||

Machine weight (approx.) |

kg |

9000 |

12500 |

14000 |

16000 |

Overall dimensions (length x width x height) |

mm |

3160×2800×3000 |

3730×3100×3100 |

4100×3100×3100 |

5100×3100×3100 |

Vertical Machining Center

Vertical Machining Center Horizontal Machining Center

Horizontal Machining Center All Gear Heavy Machining Center

All Gear Heavy Machining Center All Gear Moving Column Type Heavy Machining Center

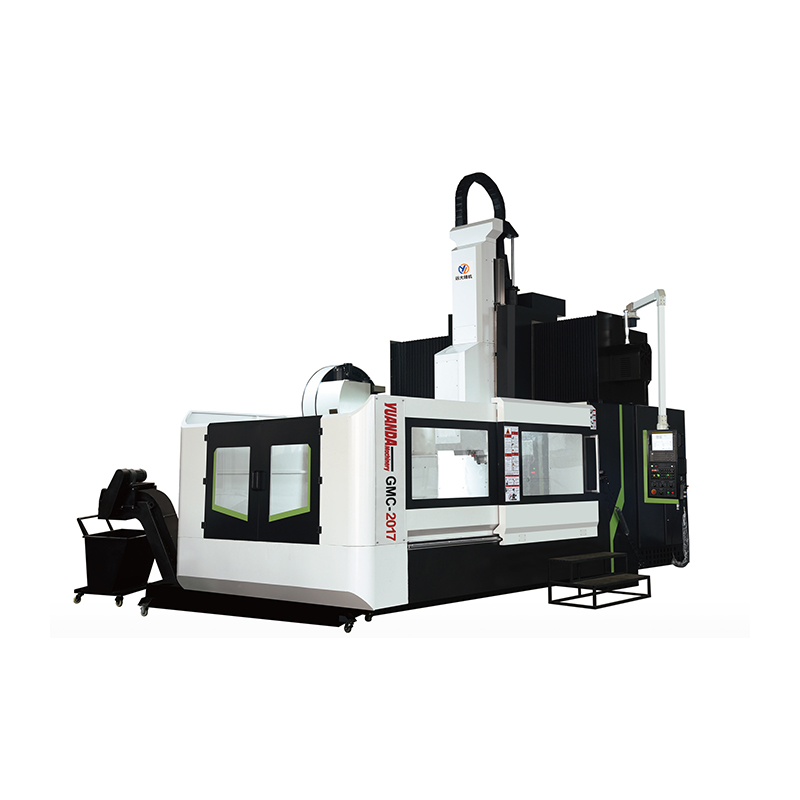

All Gear Moving Column Type Heavy Machining Center Gantry Machining Center

Gantry Machining Center All Gear Gantry Heavy Machining Center

All Gear Gantry Heavy Machining Center Oil Perforating Gun Blind Hole Special Plane

Oil Perforating Gun Blind Hole Special Plane