IZICI EZINKULU ZOBUCHWEPHESHE

1. Izingxenye eziyinhloko zethuluzi lomshini njengombhede, ikholomu, i-worktable kanye nebhokisi lokuphotha zonke zenziwe ngensimbi empunga yekhwalithi ephezulu enokumelana nokuzamazama komhlaba okuphezulu. Akhiqizwa amabhizinisi angochwepheshe aphumelele isitifiketi sesistimu yekhwalithi ye-ISO9000. Inqubo yokuphonsa isebenzisa ukucubungula okukhethekile ukuze kuthuthukiswe izakhiwo zemishini yezinto. Ukukhishwa sekuneminyaka emibili ukuze kuqedwe ukucindezeleka okusele ngaphakathi kwempahla, ngakho-ke ithuluzi lomshini linokuqina okuhle kakhulu nokumuncwa okuhle kakhulu kokushaqeka; ibuye ibe nokuzinza okuhle kokushisa kanye nokuzinza kokunemba okuhlala isikhathi eside.

2. Izindawo ezihlangene eziyinhloko zomhlangano wamathuluzi womshini zikhujwa ngokucophelela ukuze kuqinisekiswe indawo yokuxhumana esebenzayo yezindawo ezihlangene.

3. Iphini lokuphotha lamukela iyunithi yokuphotha enembile ekhiqizwa umkhiqizi ochwepheshile, futhi amabhoreyili okuphotha athatha amabhrendi ophawu lokuphotha adumile emhlabeni wonke ane-angular axhuma amabhola ukuze kuqinisekiswe ukuthi ukuphotha kunokunemba nokuqinile okuphezulu kakhulu. I-spindle kanye ne-motor pulley ihlolwe ngokulinganayo ukuze kuqinisekiswe ukunemba nempilo ye-spindle.

4. Ingxenye yokuphakelayo yethuluzi lomshini isebenzisa izikulufu zebhola ezinembe kakhulu ezingenisiwe, futhi amabheringi okusekela emikhawulweni yomibili athatha ama-screw bearings avela kwamanye amazwe, futhi izikulufu zebhola zelulwe kusengaphambili; ukuxhunywa kwe-screw-motor kusebenzisa ukuhlanganisa okunwebekayo okungenagebe, ukudlulisa akunagebe, umzuzu omncane we-inertia kanye nokuqina kokudlulisela okuphezulu.

5. Ithuluzi lomshini liklanywe kusetshenziswa i-X/Z-axis roller linear rails, futhi imizila yolayini enezinhlangothi ezimbili isebenzisa ukulayisha okusindayo, ukuze ithuluzi lomshini lingagcini nje ngokucabangela izici zejubane eliphezulu nokunemba okuphezulu, kodwa futhi izici zokusika okusindayo, ezinokuqina okuhle kakhulu nokusebenza kahle kokukhiqiza.

6. I-screw kanye ne-guide rails ifakwe phakathi kwezinto zokuthambisa ezizenzakalelayo, ezihlinzeka ngokuzenzakalelayo uwoyela ku-screw kanye ne-guide rails ngezikhathi ezithile ukuze kuqinisekiswe ukuthi ithuluzi lomshini ligcotshwe ngokugcwele ngesikhathi sokunyakaza, ngaleyo ndlela iqinisekisa ukuthi ithuluzi lomshini linempendulo enhle kakhulu esheshayo. izici nokusebenza kokuphakelayo kwesivinini esiphansi. , impilo yesevisi ende kanye nokugcinwa kokunemba okungcono.

7. Uhlelo lwe-CNC yi-GSK-980MDI, okuyisizukulwane sakamuva sohlelo lwe-CNC olulungiselelwe ngama-motor absolute servo motors.

8. Ifakwe ipuleti lenkomba ye-servo enembayo ephezulu ukuze ibone ukukhomba okuzenzakalelayo kanye nokuma kwezinto zokusebenza; ipuleti lokukhomba lifakwe i-hydraulic chuck ukubona ukugoqa okuzenzakalelayo kanye nokuxegiswa kwama-workpieces.

9. Ifakwe inzwa yokujula kwembobo eyimpumputhe, ukucutshungulwa kwembobo eyimpumputhe nokutholwa kokujula kwenziwa kanyekanye ukuze kuqinisekiswe ngokunembile izidingo zokujula kwembobo eyimpumputhe.

10. Uhlelo lokulayisha nokuthulula oluzenzekelayo luyakhethwa ukuze kuncishiswe inani labasebenzisi nokunciphisa amandla okusebenza kwabasebenzi.

Ikhaya

Ikhaya Isikhungo Somshini Esiqondile

Isikhungo Somshini Esiqondile Evundlile Machining Center

Evundlile Machining Center Zonke Gear Heavy Machining Center

Zonke Gear Heavy Machining Center Zonke Ikholomu Enyakazayo Yohlobo Lwesikhungo Esinzima Somachining

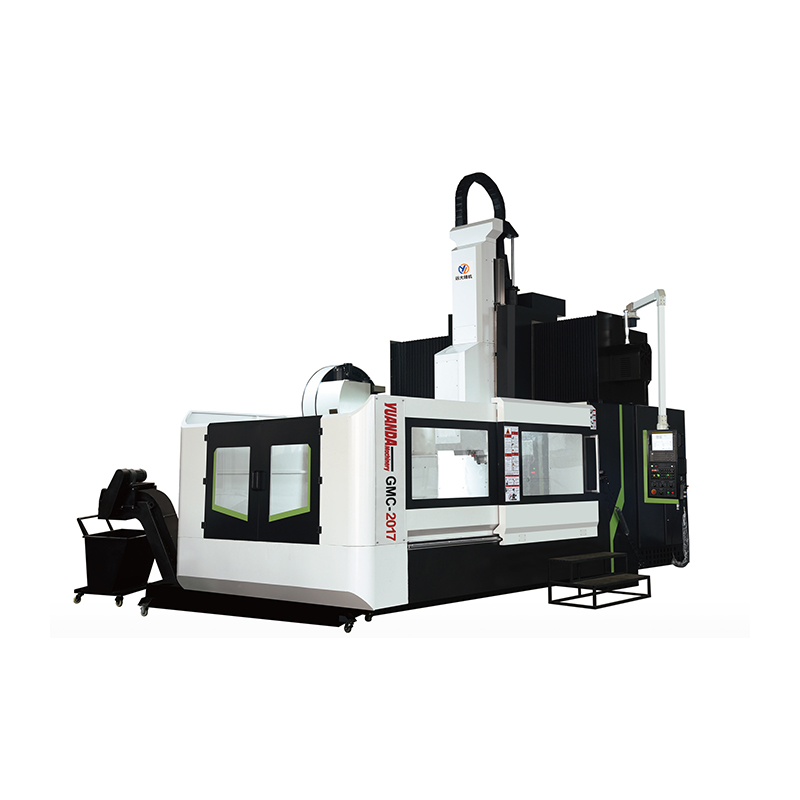

Zonke Ikholomu Enyakazayo Yohlobo Lwesikhungo Esinzima Somachining I-Gantry Machining Center

I-Gantry Machining Center Yonke Isikhungo Semishini Ye-Gear Gantry

Yonke Isikhungo Semishini Ye-Gear Gantry Indiza Eyisipesheli Yembobo Eyimpumputhe Yamafutha

Indiza Eyisipesheli Yembobo Eyimpumputhe Yamafutha