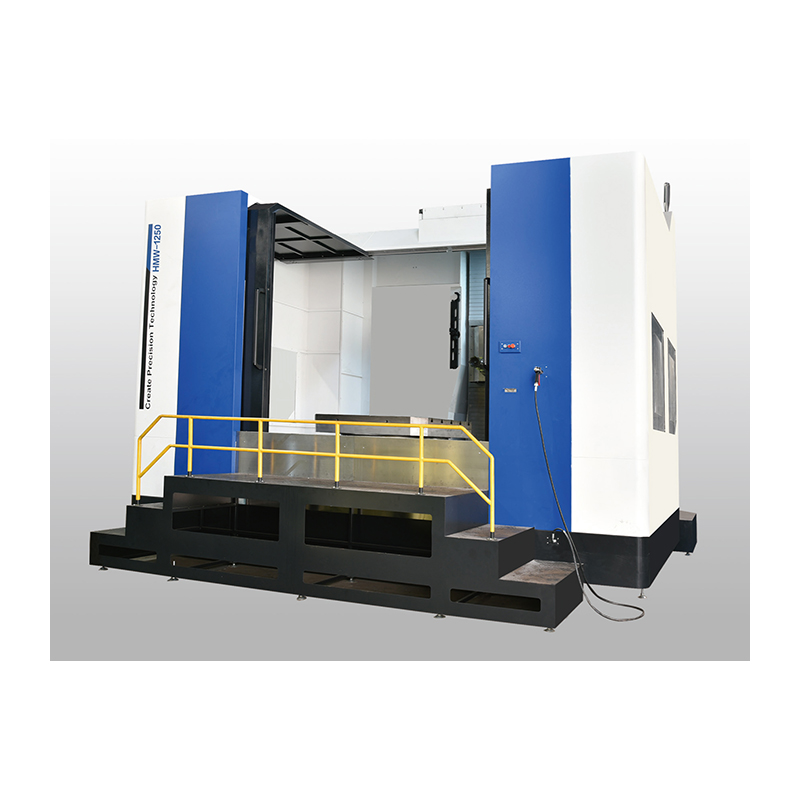

HMW-630/800/1000/1250

Project |

Unit |

HMW-630 |

HMW-800 |

HMW-1000 |

HMW-1250 |

Workbench area |

mm |

630x630 |

800x800 |

1000x1000 |

1250x1250 |

Number of workbenches |

|

Standard single workbench, optional exchangeable workbench |

|||

Minimum division of workbench |

° |

Standard: 1° x360, optional: 0.001° |

|||

Maximum load-bearing capacity of workbench |

kg |

1200 |

2000 |

3000 |

5000 |

Maximum size of workpiece (diameter x height) |

mm |

Φ1000x800 |

Φ1350x1000 |

Φ1600x1300 |

Φ2200x1500 |

X/Y/Z axis travel |

mm |

1050x800x900 |

1400x1000x1100 |

1600x1300x1100 |

220x1500x1500 |

From the center of the worktable to the end face of the spindle |

mm |

120-1020 |

200-1300 |

200-1500 |

200-1700 |

From worktable surface to spindle center |

mm |

80-880 |

80-1080 |

50-1350 |

50-1550 |

Spindle specifications |

|

BT50 |

|||

Spindle maximum speed |

rpm |

6000 |

|||

X/YIZ axis guide rail |

|

Three-line roller |

|||

X/Y/Z axis rapid movement |

m/min |

24/24/18 |

18/18/18 |

||

Maximum chip feed rate |

m/min |

10 |

|||

CNC system |

|

Optional |

|||

main motor power |

Kw |

15 |

|||

Tool magazine capacity |

|

24 |

|||

positioning accuracy |

mm |

0.01 |

0.012 |

||

Repeatability |

mm |

0.006 |

0.008 |

||

B-axis positioning accuracy |

|

土3 |

|||

B-axis repeat positioning accuracy |

|

土1 |

土2 |

||

Air demand |

kg/cm² |

≥6 |

|||

Air flow |

m³/min |

≥0.5 |

|||

Machine weight (approx.) |

T |

12.5 |

15.5 |

18.5 |

24 |

Overall dimensions (length x width x height) |

mm |

4900×3600×2850 |

5500×4200×3200 |

6000×4400×4000 |

7000×5000×4200 |

Vertical Machining Center

Vertical Machining Center Horizontal Machining Center

Horizontal Machining Center All Gear Heavy Machining Center

All Gear Heavy Machining Center All Gear Moving Column Type Heavy Machining Center

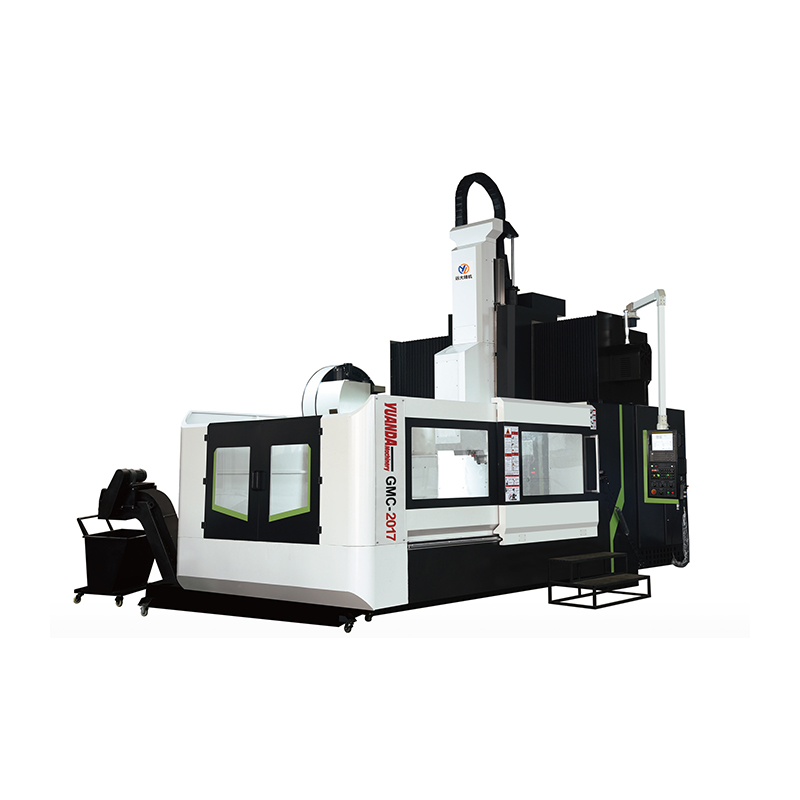

All Gear Moving Column Type Heavy Machining Center Gantry Machining Center

Gantry Machining Center All Gear Gantry Heavy Machining Center

All Gear Gantry Heavy Machining Center Oil Perforating Gun Blind Hole Special Plane

Oil Perforating Gun Blind Hole Special Plane