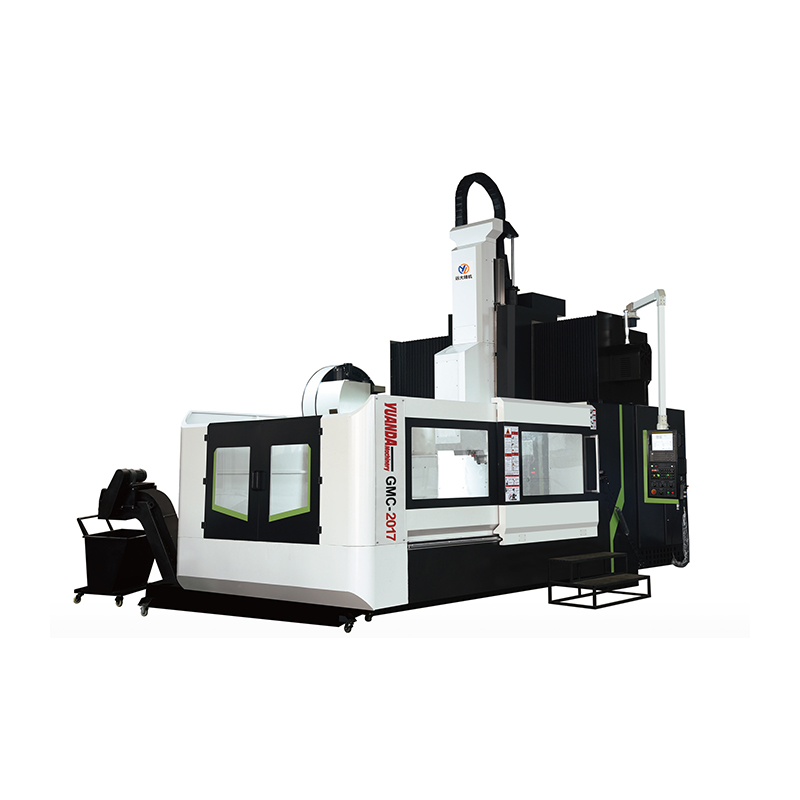

Umshini wokugaya ongukhiye we-WKX-6020 CNC ovundlile

I-WKX-6020 izici zobuchwepheshe eziyinhloko

1. Izingxenye eziyinhloko zethuluzi lomshini njengombhede, ikholomu, inqola ephambanayo kanye nebhokisi lokuphotha zonke zenziwe ngensimbi empunga yekhwalithi ephezulu enokumelana nokuzamazama komhlaba okuphezulu. Akhiqizwa amabhizinisi angochwepheshe aphumelele isitifiketi sesistimu yekhwalithi ye-ISO9000. Inqubo yokuphonsa isebenzisa ukucubungula okukhethekile ukuze kuthuthukiswe izakhiwo zemishini yezinto. Ukukhishwa sekuneminyaka emibili ukuze kuqedwe ukucindezeleka okusele ngaphakathi kwempahla, ngakho-ke ithuluzi lomshini linokuqina okuhle kakhulu nokumuncwa okuhle kakhulu kokushaqeka; ibuye ibe nokuzinza okuhle kokushisa kanye nokuzinza kokunemba okuhlala isikhathi eside.

2. Izindawo ezihlangene eziyinhloko zokuhlanganisa ithuluzi lomshini zikhujwa ngokucophelela ukuze kuqinisekiswe indawo yokuxhumana esebenzayo yezindawo ezihlangene .

3. Iphini lokuphotha lamukela iyunithi yokuphotha enembile ekhiqizwa umkhiqizi ochwepheshile, futhi amabhoreyili okuphotha athatha amabhrendi ophawu lokuphotha adumile emhlabeni wonke ane-angular axhuma amabhola ukuze kuqinisekiswe ukuthi ukuphotha kunokunemba nokuqinile okuphezulu kakhulu. I-spindle kanye ne-motor pulley ihlolwe ngokulinganayo ukuze kuqinisekiswe ukunemba nempilo ye-spindle.

4. Idrayivu ye-X-axis isebenzisa injini ye-AC servo, encishiswa ngesinciphisi segiya leplanethi engu-1:10 esingeniswe sisuka eJalimane, bese sishayela irack egiyeni ukuze kuzuzwe ukuphakelwa kwe-X-direction; lokhu kugwema ukuguquguquka kokuguquguquka kwenduku ye-filament ngenxa yesisindo sayo, ngaleyo ndlela Ithinta ukunemba kokucubungula.

Ukuhlanganiswa kokuphakelayo kwe-axis ye-Y/Z kusebenzisa izikulufu zebhola ezinemba okuphezulu ezingenisiwe, futhi amabheyiri asekelayo emikhawulweni yomibili asebenzisa ama-screw bearings akhethekile angenisiwe, futhi izikulufu zebhola zelulwe kusengaphambili; uxhumano lwe-screw-motor luthatha ukuhlanganisa okunwebekayo okunganagebe Ukudluliswa akunayo igebe, umzuzu omncane we-inertia kanye nokuqina kokudlulisela okuphezulu.

5. Idizayini yethuluzi lomshini isebenzisa ojantshi bomugqa we-X/Y/Z we-axis roller, futhi ojantshi bomugqa abanezindlela ezimbili bathatha ukulayishwa kusengaphambili okusindayo, ukuze ithuluzi lomshini lingagcini nje ngokucabangela izici zejubane eliphezulu nokunemba okuphezulu, kodwa futhi libe nakho. izici zokusika okusindayo futhi unokuqina okuhle kakhulu. kanye nokusebenza kahle kokukhiqiza.

6. I-screw, isitimela somhlahlandlela kanye ne-giya rack konke kufakwe izinto zokuthambisa ezizenzakalelayo ezimaphakathi, ezinikezela ngokuzenzakalela ku-screw, umzila wesitimela kanye ne-giya rack ngezikhathi ezithile, ukuze ithuluzi lomshini ligcotshwe ngokugcwele ngesikhathi sokunyakaza, ngaleyo ndlela kuqinisekiswe ukuthi ithuluzi lomshini linezici ezinhle kakhulu zokuphendula okusheshayo nokusebenza kokuphakelayo okunesivinini esiphansi, impilo ende yesevisi kanye nokugcinwa kokunemba okungcono.

7. Uhlelo lwe-CNC luyi-SYNTEC-22MA, ishaneli ekabili, okuwuhlelo lwakamuva lwe-CNC lwesizukulwane esihlome nge-bus absolute servo motor.

8. Isistimu yokuthola kanye nesistimu yokucubungula kulawulwa ngokwehlukana. Ngenkathi isistimu yokucubungula icubungula ukhiye, isistimu yokuthola ithola umsebenzi esiteshini esilandelayo, njalo njalo, ukukhulisa ukunemba kokucubungula nokusebenza kahle kokucubungula.

Imingcele Yezobuchwepheshe

Iphrojekthi |

Iyunithi |

I-WK-6020 |

Ibanga lobubanzi bomsebenzi wokusebenza |

mm |

Φ73-Φ102 |

Ubude besiqephu somsebenzi esiphezulu |

mm |

1220 |

Ukuhamba kwe-X-eksisi |

mm |

4500 |

Ukuhamba kwe-Y-eksisi |

mm |

100 |

Uhambo lwe-Z-eksisi |

mm |

300 |

Ukunemba kokuma kwe-eksisi ye-X/Y/Z |

mm |

0.04/0.01/0.01 |

X/Y/Z ukunemba kokuphinda kokuma kwe-eksisi |

mm |

0.03/0.008/0.008 |

I-spindle hole taper |

I-BT40 |

|

Ibanga lejubane le-spindle |

r/min |

0-2000 |

I-Servo motor rated power rated |

kw |

7.5 |

Indlela yokususa i-chip |

I-Spiral chip conveyor+Chain plate chip conveyor |

|

Indlela yokupholisa i-spindle/indlela yokupholisa |

Ukuvikelwa kwekhethini lomoya, ukupholisa ukucubungula, ukucubungula ukuvunguza komoya |

|

Umoya ocindezelwe wamathuluzi omshini |

Kgf/cm 2 |

6; 8 |

Ubukhulu bethuluzi lomshini |

mm |

7500×3500×2000 |

Isisindo somshini (cishe.) |

kg |

12000 |

Ikhaya

Ikhaya Isikhungo Somshini Esiqondile

Isikhungo Somshini Esiqondile Evundlile Machining Center

Evundlile Machining Center Zonke Gear Heavy Machining Center

Zonke Gear Heavy Machining Center Zonke Ikholomu Enyakazayo Yohlobo Lwesikhungo Esinzima Somachining

Zonke Ikholomu Enyakazayo Yohlobo Lwesikhungo Esinzima Somachining I-Gantry Machining Center

I-Gantry Machining Center Yonke Isikhungo Semishini Ye-Gear Gantry

Yonke Isikhungo Semishini Ye-Gear Gantry Indiza Eyisipesheli Yembobo Eyimpumputhe Yamafutha

Indiza Eyisipesheli Yembobo Eyimpumputhe Yamafutha